Big tech, even bigger heart, provides shields to Hatzalah

As New York experienced the worst of the COVID-19 crisis, one image that became all too familiar on the news and social media was that of a health care professional struggling to sanitize and reuse masks, scrubs, and gowns — otherwise would have been used only once — as supplies of personal protective equipment ran low. With no end and no help in sight, health care professionals started to feel desperate.

That included first responders at Riverdale Hatzalah, a volunteer Jewish ambulance service. Except the local service’s co-head coordinator — Jeffery Moerdler — found help within his own family. Even if it was across state lines.

In northern New Jersey, Jeff’s nephew Bernie Moerdler was reading the news just like everybody else. One thing set him apart, though. Moerdler, at 19, already has worked with Microsoft and, at the beginning of the pandemic, had to fly home from Israel, where he was studying at Bar-Ilan University near Tel Aviv, and working on artificial intelligence programming he hoped would someday detect cancer.

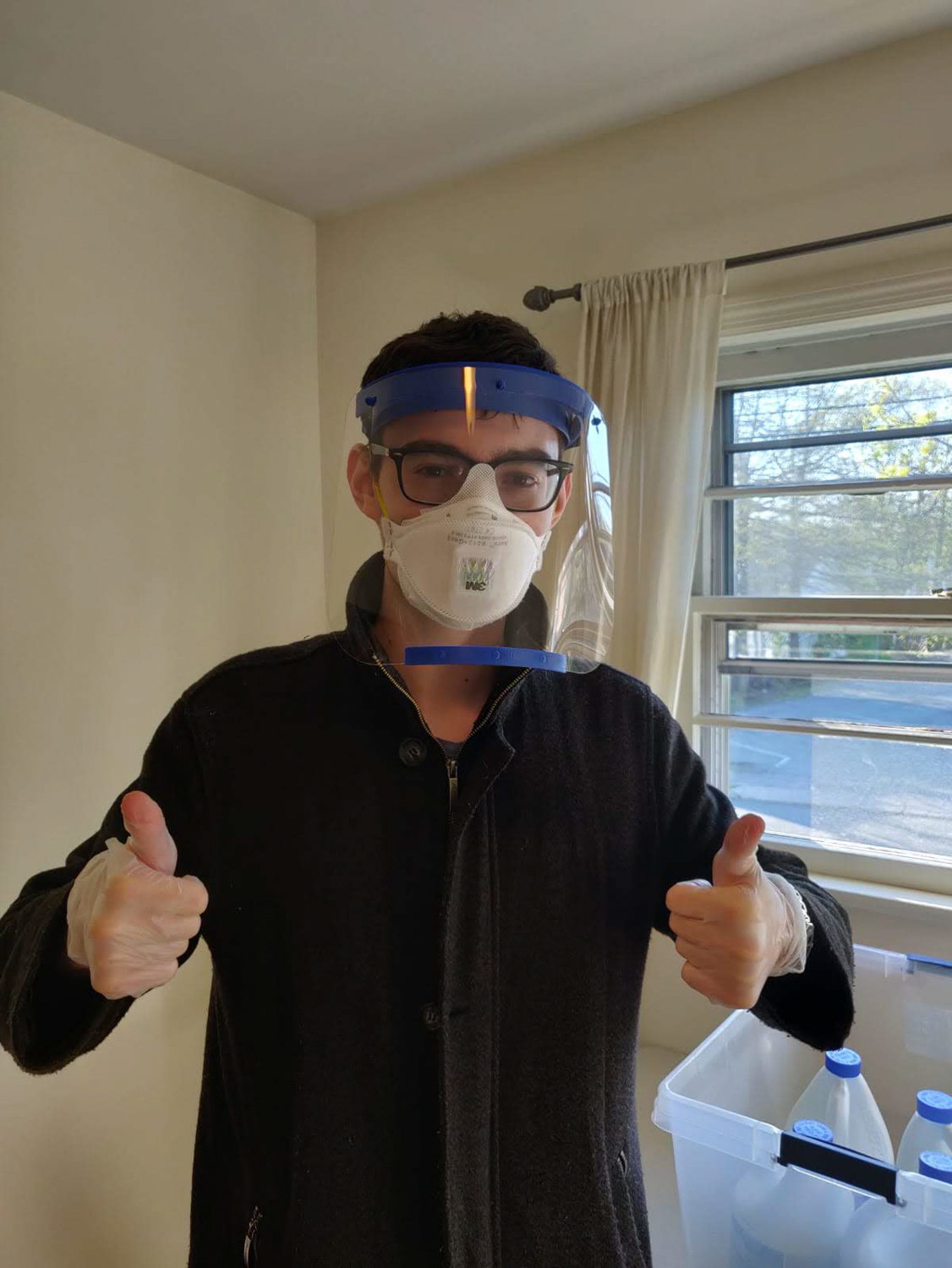

Once home, Moerdler knew he’d want to help — so he found a pattern for 3-D printing reusable plastic face shields — which are typically used alongside masks to protect health care workers from the coughing and sneezing of sick (and contagious) patients.

“I had a bar mitzvah, and I actually asked my parents for a 3-D printer,” Moerdler said. “I heard about it as an emerging technology, and I thought, ‘Wow, I’d really like to see what that’s all about.’”

That first printer was one of the first commercially available, he said, and wasn’t particularly functional. Over the years, he moved through two more models, and was excited to see the technology get better.

“When I came back, I said to myself, ‘There’s nobody doing this, really, in New Jersey,’” he said. “I have the scale, and the printers, and the support and the connections, and I could probably do it pretty easily.”

Moerdler mentioned the idea to his friend, Daniel Mezhiborsky, and the project took on a life of its own.

The company that released the design for the shields was the same one who sold Moerdler his printer, and he had worked with them previously testing products.

Right now, Fair Lawn Face Shields — the name of Moerdler’s project — can print around 22 shields per day on five 3-D printers and a laser cutter, which they use to cut down and shape large sheets of plastic into the curved final product.

“We have these large pieces of plastic which we then cut down, we cut them down to about the size of a piece of a paper,” Moerdler said. “And then use the laser cutter to cut that down to the actual shape of the shield. Then the other items — including our elastic, which we use in the shields — and a chin piece, which is a support piece, which is also 3-D printed, go into the clean room.”

Mezhiborsky and Moerdler started crowdfunding online to raise money to keep the project going, he said, raising just shy of $4,000 by the end of June.

The pieces are washed in a bleach solution for two minutes, left to dry, and then sealed into plastic bags and shipped off, Moerdler said, trying to keep everything “as clean as possible” for the emergency responders and hospitals receiving them.

Jeffrey Moerdler was one of the first people Bernie reached out to about the shields, he said, knowing that he and the Hatzalah crew were responding to calls every day.

“I said to him, like, I’m thinking of doing this, would you guys need any?’” Bernie Moerdler said. “He jumped on it, once we got started, he was put in the system for orders.”

They’ve also delivered to St. Barnabas hospital in Belmont, although the bulk of their business has been to fire departments, nurses and EMS departments in New Jersey.

New York and New Jersey are slowly beginning to reopen as COVID cases and hospitalizations continue to drop, although spikes across the country are keeping everyone on their toes for the oft-discussed “second wave” of the virus.

To that end, Moerdler said, production of the shields has slowed down somewhat.

“We aren’t stopping anything, so we’re just going to keep building as much as we can, as long as the GoFundMe continues and things like that,” he said. “We’ll just keep on producing as much as we can.”

If there is a second wave after production indeed stops, they’ll be prepared to boot the operation up again and start churning out shields. They’re not disposable, Moerdler said, but can be sanitized and reused, which might reduce some of the need for new equipment in the face of future infections.

“We want to just help out as many people as possible,” Moerdler said. “I guess the most important thing is that if anyone knows anyone — whether it be a nursing home or a first responder’s group or anything — that’s in need, to really just send them to fill out that form.”

That form, by the way, can be found at BMoerdler.com/faceshields.